Stormseal is a polyethylene film that heat-shrinks to securely wrap a damaged roof or structure.

Unlike tarps, Stormseal stays put until permanent repairs can be made, resisting wind, rain and hail and preventing further costly damage.

This award-winning innovation saves insurers tens of millions of dollars and has won the hearts of countless policyholders.

Stormsealed properties worldwide

Including more than 4,000 in US. View our Stormseal gallery.

Watertight

Stormseal is also resistant to further storms including hail and winds up to 100mph.

Months or more of protection

Stormseal can last over a year, giving you peace of mind until final repairs are made. See our extreme test in the Swiss Alps.

Why use Stormseal

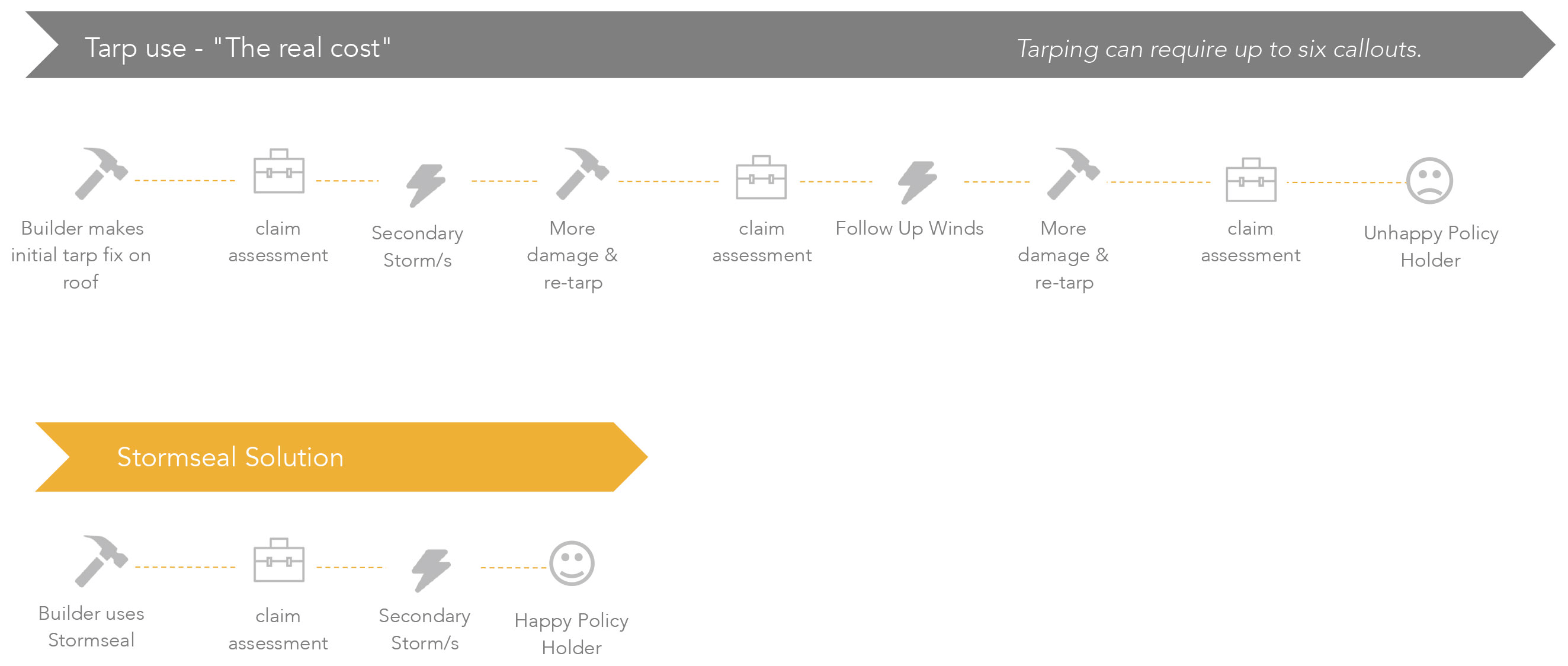

When severe storms strike, TPAs and contractors usually attempt to protect damaged properties with tarps. When the weather turns wet or windy again, tarps inevitably slip, blow off, leak or collapse under the weight of pooling rainwater.

Over the life of an insurance claim, tarps fail five times on average and up to 13 times.

This results in costly outcomes for insurers:

- Property damage increases, escalating insurance claims. Sometimes more than 10-fold after a major storm

- Call center staff receive repeated complaints and requests for tarp replacement from distressed, angry or even injured policyholders

- Contractors return repeatedly to replace failed tarps at the insurer’s expense

- Assessors return repeatedly to evaluate fresh damage, at the insurer’s expense

- Claims resolution and permanent repairs are delayed

- Some properties become uninhabitable, so occupants are re-housed at the insurer’s expense

- Policyholders switch insurers seeking a better service

- Frustrated policyholders vent on social media and in the press, damaging their insurer’s reputation

In contrast, Stormseal goes on once and stays on for as long as it takes to repair the roof. This prevents further damage and costs, plus you enjoy the gratitude and loyalty of happy policyholders.

See Stormseal in action

Start using Stormseal

Give us a call on (561) 588 5653 or email sales@stormseal.com to find out how to cut your costs and boost customer satisfaction with Stormseal.

Our solution is a complete system of online ordering, distribution, and accredited installer training. Our quality assurance processes cover manufacture through to installation. Find out more in the FAQs below or get in touch.

FAQs

Stormseal is far more cost-effective than tarps. Tarps are cheaper to procure but they multiply claims costs by causing further property damage when they frequently flap, tear, leak, collapse or flyaway. Labour costs are also greater for tarps because they require repeated replacement – 4 to 5 times on average, and up to 13 times – during the months it takes to process a damage claim.

Another cost of tarps is loss of customer goodwill. Customers are traumatised as their home suffers further weather damage and the noise of flapping tarps keeps them awake at night. They experience extreme frustration when they have to call their insurer repeatedly to ask for failed tarps to be replaced. In contrast, Stormseal customers are very satisfied because they experience minimal disruption to their lives and have peace of mind knowing their home is secure.

Installers save time by using Stormseal. Tarp installation time includes the time taken to procure supplies of tarps, sandbags and ropes for each job, as contractors generally don’t carry these on their trucks. Frequently, the first tarp purchased is the wrong size, which means a return trip to the hardware store.

Meanwhile, with a roll of film and complete toolbox already on their truck, the Stormseal installer has cut the film on-site to fit the job, and commenced attachment. One roll of Stormseal holds 1500 sq ft, or enough film for 10 average dry-in jobs. This equates to about two days’ work without stopping for further supplies.

When repeat visits to replace failed tarps are added to the account, it’s clear that as Stormseal resists all weather and stays put until permanent repairs can be made, it saves contractors vast amounts of time and cuts insurers’ costs dramatically.

We prioritize the safety of workers, residents and properties and discourage practices that increase risks and escalate costs. We’re proud of Stormseal’s excellent reputation and intend to maintain it. To ensure safety and quality, accountability is key. Our solution is a complete system of accredited installer training, specialist equipment, controlled ordering and performance tracking, so our quality assurance processes cover everything from manufacture to installation.

Only accredited installers can order Stormseal film and a toolkit containing everything needed for correct installation. Instead of relying on ropes, sandbags and “Hail Mary’s” to hold a tarp in place (and when that fails, returning repeatedly to replace the tarp), Stormseal installers do the job once and do it right.

At Stormseal, poor performance means loss of accreditation for the installer. By contrast, in Australia, when a tarp (almost inevitably) performs poorly and requires replacement, the installer is rewarded with an additional dry-in fee from the insurer. Insurers pass these additional costs on to policyholders as higher premiums. Premiums also rise as claims escalate due to additional property damage caused by flapping, leaking tarps.

Storm victims who suffer under tarps and customers hit with higher premiums are likely to seek a better alternative, i.e. an insurer who uses Stormseal to provide a superior customer experience and keep costs down. Our insistence on safety and cost-effective high quality is positively transforming the insurance repairs industry

Our installers mechanically fix all edges of the Stormseal film securely, often to the eaves of the structure. The risk of secondary damage on removal of the film is low, and if it occurs, the cost of replacing fascia boards or some roof tiles is negligible compared to the massive cost of internal damage to properties caused by flapping, leaking, flyaway tarps.

Property damage is also caused by the sandbags and ropes used with tarps. Ropes are often tied to any available attachment point including gutter brackets, down-pipes, gas/water lines and fences. Under the load of wind or pooling rainwater on the tarp, the ropes’ attachment points are frequently damaged. Sandbags break down within six weeks of weather exposure and the sand escapes, filling gutters and valleys to create barriers that force water back into the roof cavity, causing more internal damage.

Stormseal minimizes harm. Tarps, ropes and sandbags frequently cause damage claims to multiply manifold. The superior choice is obvious.

No. We hold inventory and dispatch Stormseal film from our stock when an accredited installer places an order online through our customer portal. We have capacity to scale up film production to meet high demand following a severe weather event.

Yes, Stormseal can cover a full roof if damage is total. However, the product is more often used to cover partial roof damage, e.g. tree impact on one side, or fire damage contained to one area.

Yes, Stormseal can be used to cover partial roof damage, e.g. a damaged roof vents, a section of broken tiles, or over skylights.

IAG has conducted hail testing on the product, please see the video at: https://youtu.be/rKiFqvavj-Y

Wind tunnel testing has been conducted by CSR and by the HAAG wind tunnel test facility located in Dallas TX. See CSR wind video at: https://youtu.be/0X7w-kF_zXk

Yes, the product can be used for walls, windows, ceilings, garage doors, asbestos removal.

Stormseal film is recyclable; it is not biodegradable. Stormseal film can be repurposed – unlike damaged tarps which generally go to landfill.

Stormseal requires mechanical fixings to ensure the film fits snugly to your home or business. So instead of ropes or sandbags Stormseal is fixed at the perimeter like the fascia, barge boards or eaves.

Yes, Stormseal film is warranted for one year from the time of purchase. The installation guarantee depends on the individual Accredited Installer’s terms and conditions.

Yes, Stormseal film can be produced in many colours. Branding / logos can be printed on the film –minimum volumes apply.

Yes. An access area can be cut out of the film and then resealed. In every installation there’s a checklist sticker applied to the film. The checklist indicates claim number and installer number so you can track it down.

Yes. Accredited Stormseal installers are trained to complete a roof report before installing the film. If further assessment is required, contractors often cut inspection panels, in which case an accredited installer must remove and replace the Stormseal film. In every installation there’s a checklist sticker applied to the film. The checklist indicates claim number and installer number Similarly, insurers pay for tarps to be removed for roof inspections and replaced.

Stormseal is proudly manufactured in the Unites States of America. Stormseal is also focused on safety and quality with a commitment to ethical, sustainable, local production with zero-waste in manufacturing. There are also back up suppliers available in Australia and UK.